As a long-time enthusiast in the world of 3D printing, I’ve explored various machines, from the reliable Ender 3 V2 to the advanced Bambu Labs P1S and Prusa MK4. My journey even led me into 3D CAD design, creating custom cases and parts. However, the idea of a truly portable, “Travelling Printer” always lingered in the back of my mind. That’s why the Positron V3.2 piqued my interest – a uniquely designed machine that promises mobility without sacrificing functionality.

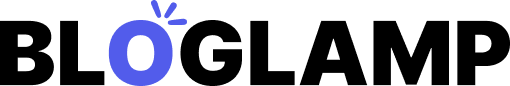

Upside-down benchy on Positron V3.2 bed

Upside-down benchy on Positron V3.2 bed

What Makes the Positron V3.2 a Standout Travelling Printer?

The Positron V3.2 isn’t your average 3D printer. Inspired by K R A L Y N 3D’s innovative design, and brought to life as a kit by LDO Motors and Positron3D, this printer immediately grabs attention with its upside-down configuration. While some might question the inverted approach, its brilliance lies in its portability. Unlike traditional printers with sprawling frames, the Positron V3.2 cleverly houses almost all its components within the base. This design choice is crucial for a travelling printer, keeping the center of gravity low and making it remarkably compact and stable for transport. The kit even comes with a hard carry case, further emphasizing its travel-ready nature. Imagine taking a capable 3D printer on the road – the Positron V3.2 is engineered to make this a reality.

Unique Features for On-the-Go 3D Printing

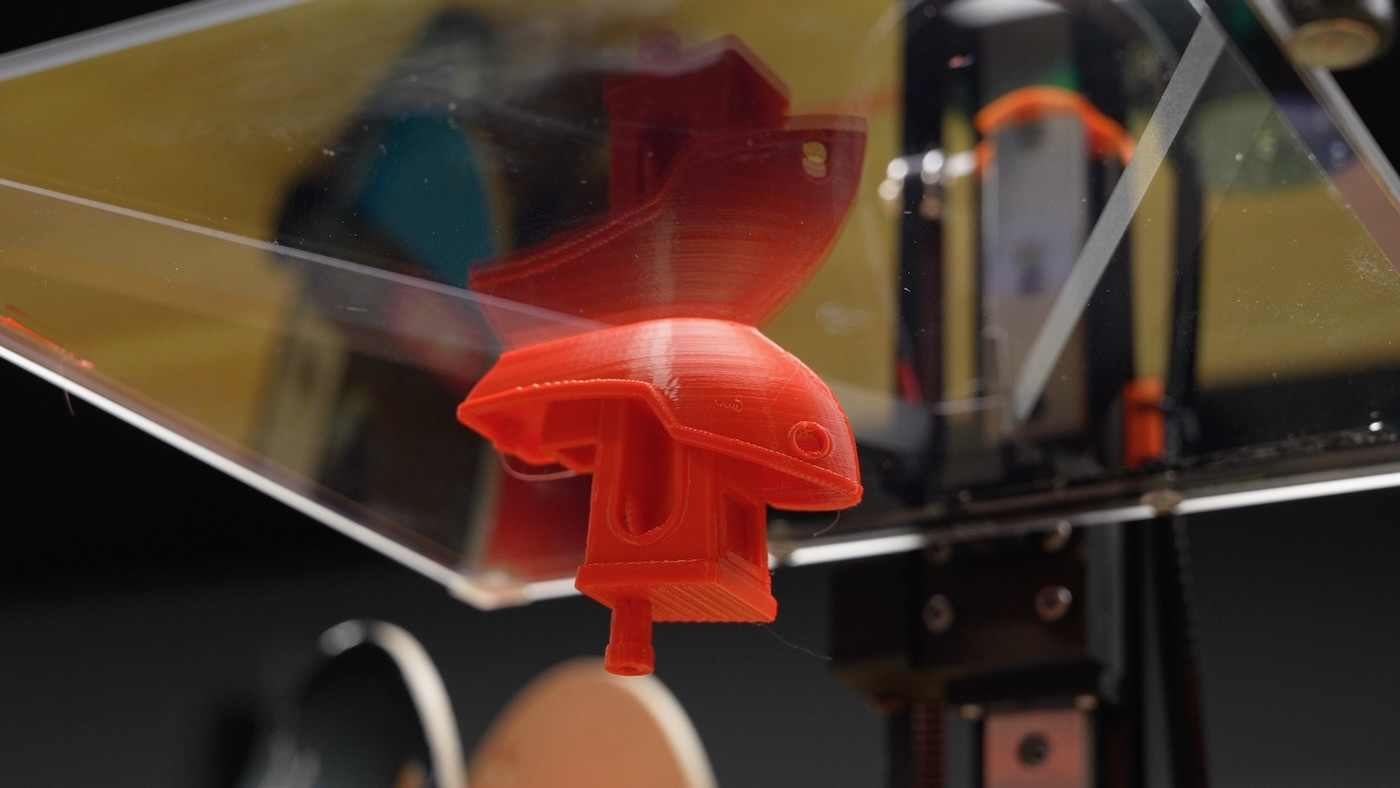

Beyond its form factor, the Positron V3.2 boasts features that cater specifically to mobile use. The heated bed, constructed from borosilicate glass coated with Indium Tin Oxide (ITO), is a standout. This technology, similar to defrosting systems in aircraft, ensures even heating across the bed with remarkable efficiency, ideal for consistent prints even when you’re not in a controlled workshop environment. While optimized for PLA, a user-friendly material perfect for on-the-go projects, the printer’s power consumption is also noteworthy for a travelling printer. As demonstrated by testing in a local park, the Positron can operate on portable battery power, consuming a modest 50-150W during printing and idling at around 20W. This opens up possibilities for truly remote 3D printing, powered by batteries or even solar solutions, making it a genuine travelling fabrication lab.

Positron on car trunk

Positron on car trunk

Building Your Mobile 3D Printing Setup

Assembling the Positron V3.2 kit is an engaging experience, different from simply unboxing a pre-built machine. It provides a deeper understanding of the printer’s mechanics, which can be invaluable when using it as a travelling printer in potentially less-than-ideal conditions. The inclusion of a Raspberry Pi CM4 as the controller unlocks advanced capabilities through Klipper firmware. Klipper’s flexibility and remote control features become particularly advantageous for a travelling printer setup. Imagine monitoring and controlling your prints from a distance, ensuring smooth operation even when you’re not physically beside the machine.

Considerations for Taking Your Prints on the Road

While the Positron V3.2 is an exciting prospect for a travelling printer, there are a few points to consider. The price point, while reflecting the quality components and unique design, is a significant investment. Additionally, the upside-down printing mechanism can sometimes lead to minor filament oozing at the nozzle, requiring occasional clean-up. However, this is a manageable issue, potentially mitigated with Klipper macro adjustments. Furthermore, the printer is best suited for materials like PLA, given the hot end and heated bed limitations for higher-temperature filaments. For most portable printing needs, especially when prototyping or creating fun, functional prints on the go, PLA is often sufficient and easy to handle.

Is the Positron V3.2 Your Ideal Travelling Printer?

The Positron V3.2 presents a compelling case as a true travelling printer. Its unique upside-down design, portability-focused engineering, and efficient operation set it apart from conventional machines. While the price may be a barrier for some, the features and capabilities, especially for those needing a mobile fabrication solution, are undeniable. If you envision 3D printing beyond the confines of your workshop, whether for outdoor projects, remote locations, or simply the convenience of a transportable machine, the Positron V3.2 is definitely worth exploring. You can delve deeper into its open-source designs and software on Positron3D’s GitHub or explore kits available through Positron3D’s website, partnered with LDO Motors. For a closer look at the build and performance, consider checking out video reviews online. The Positron V3.2 is pushing the boundaries of where 3D printing can go, literally.